COR Bio

COR Bio

COR Bio features an unprecedented combination of toughness, biocompatibility, and autoclavability – a critical triad for end-use healthcare and consumer applications.

Why COR Bio?

End Use Additive Manufacturing for Healthcare & Consumer

COR Bio is your new secret weapon for accelerating biomedical innovation and unlocking distributed digital manufacturing of consumer products. Finally, a resin that is capable of providing a safe and durable alternative to injection-molding.

Medical-grade performance in additive manufacturing has never been more accessible.

Flexible & Ductile

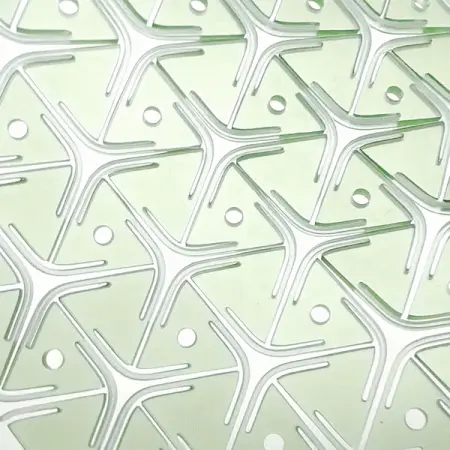

COR Bio can be rigid or flexible, depending on the thickness. Boasting extreme ductility with 100% elongation at break, it is one of the toughest photopolymers on the market.

Tough & High Impact

COR Bio provides the toughness and durability of a medical-grade theromplastic & the impact strength of an engineering thermoset. Now that you finally have a resin that can provide a safe alternative to injection molding, what will you design?

Accurate & Autoclavable

Cyclic Olefin Resins have incredibly low volumetric shrinkage - giving engineers the confidence they need to print accurate parts. The combination of COR Bio’s high working temperature and low moisture absorption unlocks a unique resilience to steam autoclave sterilization, key for many medical device applications.

Take Your Onsite Additive Manufacturing to the Next Level with COR Bio

COR photopolymer resins are intended for use by trained additive manufacturing professionals working in industrial, manufacturing, and laboratory facilities. At this time, we discourage printing with COR in home or office environments.

Please review the documentation before ordering resin.

Read the DocsPlease review the documentation before ordering resin.

Not Ready for Resin?

Don’t have the right equipment? No problem.

polySpectra can print COR Bio parts for you. Simply drag and drop your CAD or 3D model file for an instant quote.

Get an Instant QuotepolySpectra can print COR Bio parts for you. Simply drag and drop your CAD or 3D model file for an instant quote.

Rugged resin you can trust.

The core is COR.

COR stands for Cyclic Olefin Resin, a new family of engineering-grade materials for additive manufacturing developed by polySpectra. All of our COR materials feature:

- Impressive Impact Strength

- High Working Temperatures

- Moisture- and Chemical-Resistance

- Biocompatibility